-

450K+US Light Commercial

-

160K+ Convenience Stores

1

-

36K+ Supermarkets / Grocery Stores

2

-

160K+ Quick Serve Restaurants

3

-

80K+ Sit-down / Casual Dining Restaurants

4

-

18K+ Florists

5

-

Large Commercial/Specialty

-

Food Processing and Distribution

6

-

28K food processing facilities

-

500 represent 36% of output

-

2,500+ food distribution companies

-

375 locations across top 50 distributors

-

DataCenters

-

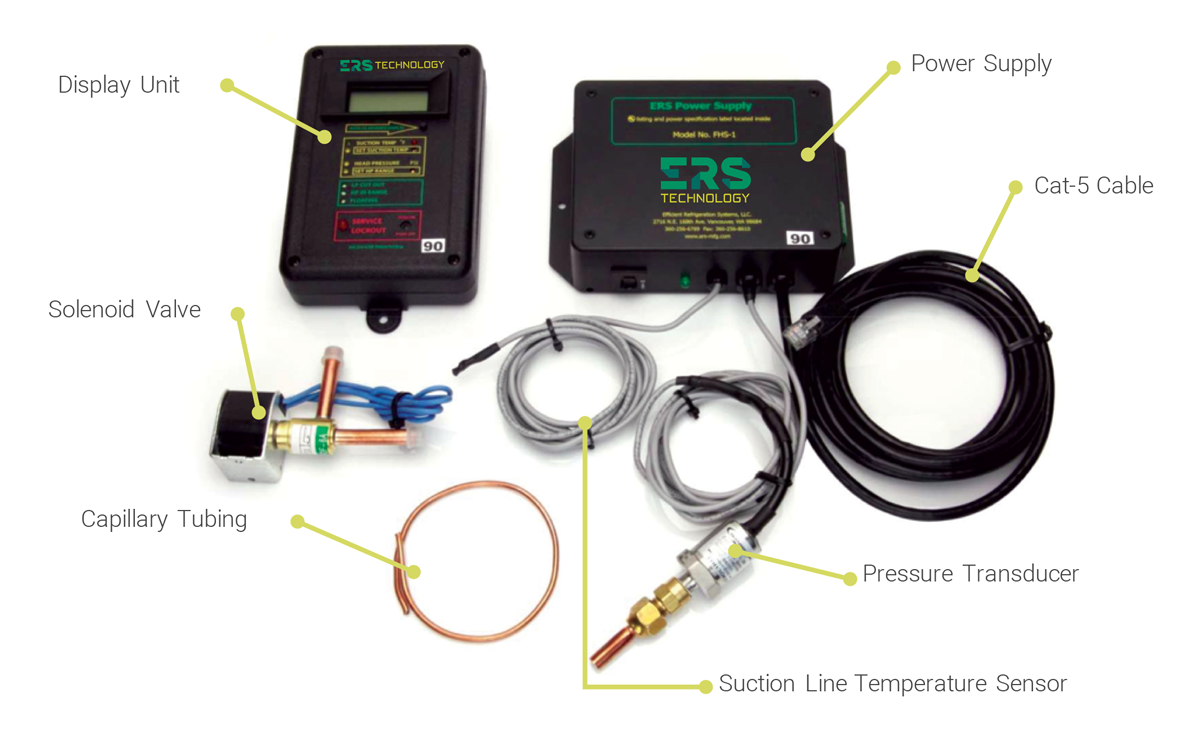

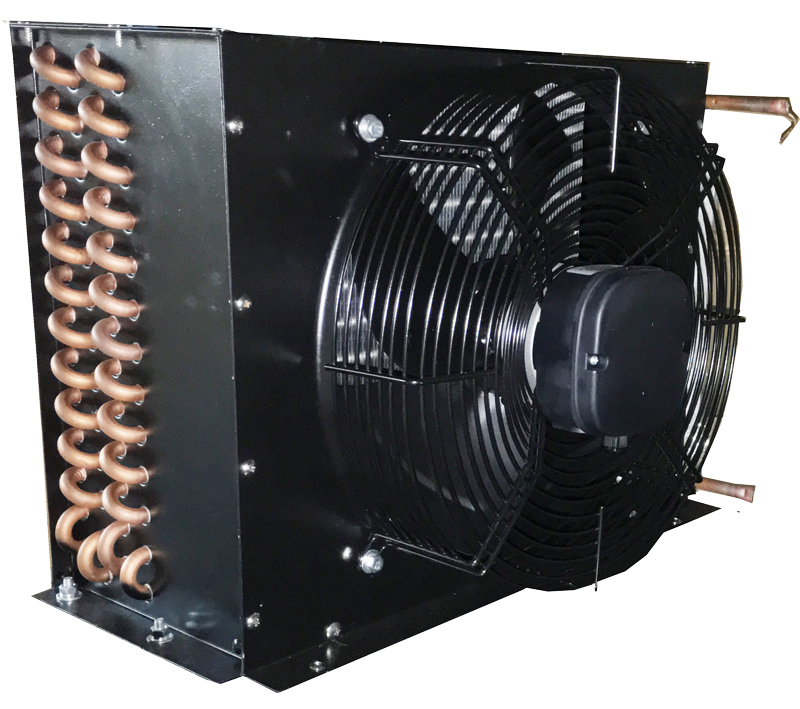

Split system refrigeration equipment

-

Equipment Types

-

Walk-in coolers and freezers

-

Reach-in refrigerated cases

-

Refrigerated multi deck and “coffin cases”

-

Data center air conditioning applications

-

US Commercial refrigeration market and installed base

-

$7.5B+ in equipment sales and service

1

-

2M+ display cases

2

-

$1B+ / 200K+ annual unit sales

-

1M+ walk-ins freezers and coolers

2

-

$800M / 40K+ annual unit sales

1 – EIA/NCIA, 2 – FMI, 3 - Pew, 4 – USA Today, 5 – USCensus, 6 – US Dept. Commerce, 7 - Emerson, 8 – Freedonia Group, 9 – US Dept of Energy